Importance of PMT in CNC systems

Posted on Jul 14 2023

by Rajashree

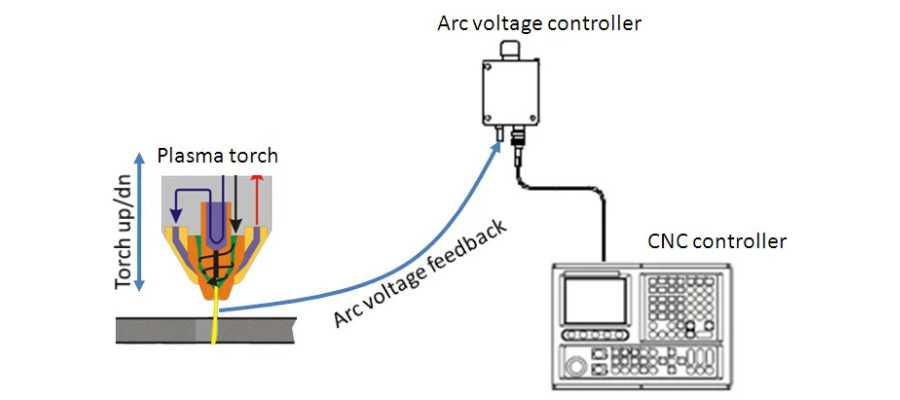

PMT which is our model for Initial Height sensing (IHS) and Auto height control is a standard part of our CNC system. PMT helps in increasing Consumable life and gives good cutting finish. This is a very important part for Plasma cutting process. It involves a PLC system which is incorporated with the Controller.

PMT is a programmable feature which when given cutting command, torch goes down to the job and starts piercing and it goes down till the required height. After piercing, torch comes up and then maintains the required height for cutting a particular thickness. This full procedure is fully automatic and programmed. The operator only feeds the plate thickness and program takes care of the full process. This allows the torch to pierce through the plate without damaging the consumables because as piercing starts, torch travels up and so the molten metal does not hit the torch.

In other make CNC systems, only Auto height control is present. In such systems, when cutting starts, the torch pierces and then comes up and maintains a standard fixed height which needs to be fed into the system by the operator. In these cases, the torch and consumables get damaged faster. The height needs to be specified by the operator based on his trial and errors.

Many a times, it has been seen that Piercing in higher thicknesses is not successfully done by other CNC systems but the same torch when fitted on our CNC system, piercing is successfully carried out. This is possible because of PMT.

PMT type system is usually not provided in standard CNC systems available in the market, they give Auto height control which they call as IHS. In the best of the brands in the world, PMT type system alone costs approx. 10 – 12 lakhs